How many of us can say we have had a real Eureka moment? How many more can say they actually had it while in the bath? And, most important of all, how many can say they acted on this idea and created something meaningful and lasting with it? Well, there was Archimedes of course; and more recently, Mark Darby of Zip Buddy.

Quite often, the measure of a good idea is the ability to reveal its value quickly, clearly and decisively. The first Zip Buddy did just that. Designed to hang freely from a zip-pull, it was a small square of printed, resin-covered label, within a moulded rubber frame with a miniature football scarf coming out of it. This could be on a hoody, a rucksack, sportsbag or any other item with a zip. From his base in Lincolnshire, the company’s owner, Mark Darby visited a number of football clubs (as well as his own team, Tottenham Hotspur) and very quickly took orders for thousands of Zip Buddys.

Taking orders for the product appeared to be the easy part. The biggest challenge for Mark was producing the Zip Buddys. “Once we started having to produce thousands, there were a few technical issues to deal with,” he says, adding, “I ended up flying to China to look at how they were producing them, but whatever they tried, they just couldn’t get it right. Fortunately, an old colleague of mine at Dupont pointed me in the direction of Liquid Lens and that is when Zip Buddy really started pulling things together!”

A System That Works

Mark rang Liquid Lens and explained what was required and they invited him to their office in Leighton Buzzard to demonstrate their system. “Having spent many months going around the world looking for a way to get the resin onto the Zip Buddys, it took little more than half an hour at liquid Lens to see that this was the perfect solution. They were able to create exactly what I was looking for with a very high quality resin and a fast, reliable process. I placed an order on the spot for the machinery to replicate their system in my own workshop,” explains Mark.

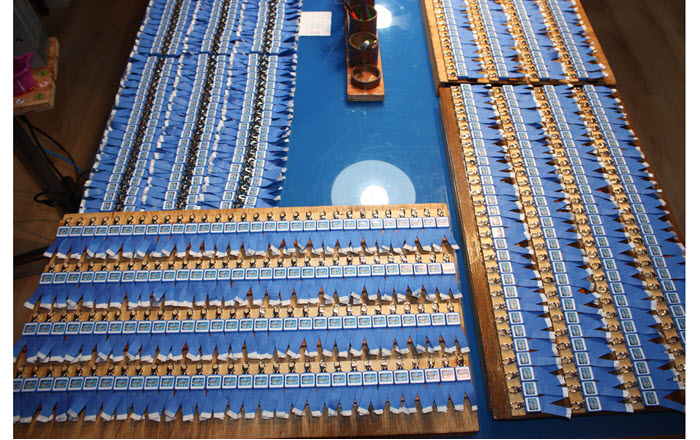

True to his word, in 2009, he became one of the first people in the UK to take ownership of the new Opal Domed Label Application machine. This was part of a complete system that included a Canon iPF 650 printer and Summa D75 cutter. “I converted a room in our house into a workshop and set up the system using the dining table as a work surface. I adapted the application area to allow me to slide the applicator along and thereby create a 5 metre working strip. The pedal operated system allows me to apply resin accurately and cleanly to the labels very quickly. From a single 400ml resin cartridge, I can fulfil over 1000 labels in around 12 minutes.”

Since the original football tags, Zip Buddy has developed a huge range of products based on the same innovative idea. Mark says, “Thanks to ease-of-use and quality of the Liquid Lens system, we have been able to design and develop all kinds of new Zip Buddys. We print them double-sided and have literally thousands of designs. We have put together a particularly good product for the RSPB which has their logo on one side and a selection of local birds on the other. These are very popular and have been a steady on-going stream of business for us as well as a regular revenue stream for the charity. We have also worked with many other charities and promotional companies and are looking to further develop this side of the business.”

Steve Hastie, Manging Director of Liquid Lens, adds, “Zip Buddy is a perfect demonstration of the quality of our resin and the ease of use and reliability of our production system. While it is an apparently simple process, it is key that the resin is able to sit where it is meant to be, is applied in a fast and consistent way and dries into a clear, clean and durable product. We helped take the complexity out of the production process and have enabled Zip Buddy to focus on developing products and fulfilling orders.”

In conclusion, Mark Darby says, “From a bathtub in Egypt, to a dining room in Lincolnshire, the journey of Zip Buddy has been exotic and exciting. However, I can’t say enough about how important Liquid Lens has been to the success of the business. They have given us a fantastic system for printing and shaping our labels and a resin application system that means we can offer a fast, high quality product that looks great and lasts for years.”

Published on: January 29th, 2020