Over the past couple of months, Sharon Lee have been busy working behind the scenes, testing and developing a range of new branding techniques that can be achieved in-house.

We are excited to announce that Sharon Lee are now in a position to offer 3D embroidery on all stocked head wear.

Using state of the art Tajima machines and a lot of know how, they can now offer near bespoke quality 3D embroidery from the UK. Lead Times are subject to the complexity and size of the logo and can be confirmed on receipt of artwork

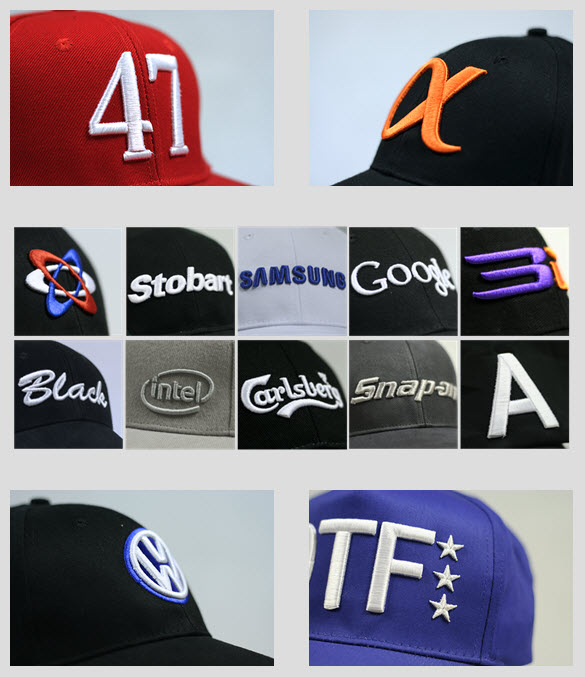

Below are just a few examples of what can be achieved:

Before you grab the phone, below are a number of key elements to keep in mind, so as to end up with a clean, crisp 3D design.

• KEEP IT THICK – Thick lettering or shapes from 3mm to 12.7mm – any less and the foam will be lost.

• SPACING – Good spacing between lettering/shapes is essential, 3mm or more will allow for a crisp clean finish.

• SMOOTH – Rounded off or smooth endpoints allow for a cleaner finish and reduce the risk of excess foam creeping out from behind the logo.

• KEEP IT SIMPLE – try to keep the design as simple as possible, removing any unnecessary loops and curls.

• GAPS – where there are parts of the logo with gaps such as the letter “e” or “o” the choice of font / logo is crucial. If the gap is too small the stitching will pull into the gap losing the letter definition. Making sure there is a clear 3mm gap will overcome this issue.

NOT ALL DESIGNS WILL WORK. IF IN DOUBT CONTACT BY EMAIL WITH YOUR LOGO AND THEIR TEAM OF EXPERTS WILL ADVISE WHAT CAN AND CAN’T BE DONE.

Please enquire here

Published on: July 23rd, 2014